Modernizing Industrial Workspaces: The Essential Technologies Transforming Efficiency and Safety

Industrial environments are evolving faster than ever. From smart robotics to AI-driven analytics, the convergence of digital intelligence and automation is reshaping how we think about productivity, sustainability, and human well-being at work. This article explores the key technologies that are re-engineering the modern industrial workspace — making operations more agile, efficient, and secure.

Summary

Modern industrial technologies now integrate AI-driven automation, IoT monitoring, digital twins, and wearable safety systems to create workplaces that are not only more productive but safer and more adaptable. Companies adopting these systems are seeing efficiency gains of 20–40%, significant energy optimization, and measurable improvements in worker safety compliance.

1. Intelligent Automation: The New Industrial Core

Enterprises across manufacturing, logistics, and energy sectors are leveraging advancements in automation and control computing to streamline production and maintain competitiveness.

Modern hardware platforms designed for real-time precision and seamless integration are enabling businesses to operate globally with consistency and reliability. These systems bring together edge computing, machine learning, and predictive control, ensuring machinery operates at peak efficiency while minimizing downtime and error rates.

For further exploration of automation software ecosystems, see:

2. The Digital Twin Revolution

Digital twins—virtual replicas of physical systems—are now central to modern industrial design. They allow real-time simulation, maintenance prediction, and optimization of plant performance before real-world deployment.

Predict failures using AI-based anomaly detection.

Optimize workflows using virtual modeling.

Improve sustainability through digital resource tracking.

Learn more from IBM’s Digital Twin Exchange.

3. Sensor-Driven Workspaces: IoT and Data Fusion

IoT-driven environments are redefining operational transparency. Industrial sensors capture everything, from equipment temperature to human movement, and feed it into a unified analytics layer. Increasingly, machine vision systems are becoming a critical part of this ecosystem. Companies such as Scorpion Vision provide advanced machine vision cameras and imaging solutions that enable real-time inspection, process validation, and intelligent monitoring. When paired with edge AI, these visual data streams drive proactive maintenance, automated quality control, and safety interventions with greater precision and speed.

Key Benefits:

Reduced downtime through real-time monitoring

Predictive maintenance with machine learning integration

Smarter energy management via environmental sensors

Discover more about industrial IoT architectures at Cisco’s IoT Edge solutions.

4. Workplace Safety Tech: The Human Layer

The safety frontier has shifted from compliance to anticipation. Modern safety systems employ computer vision, biometric sensors, and AI-based hazard detection to prevent accidents before they happen. Wearables alert workers of proximity risks, while smart helmets monitor fatigue, exposure, and stress levels.

Example innovations:

5. Industrial AI Integration Checklist

Use this checklist to ensure your workspace modernization plan covers all operational layers:

6. How-To: Build a Smarter, Safer Industrial Ecosystem

Step 1: Diagnose

Audit your current systems for inefficiencies, safety gaps, and data blind spots.

Step 2: Prioritize Integration

Select interoperable technologies—automation platforms, IoT gateways, and safety analytics tools—that share data seamlessly.

Step 3: Implement Edge & Cloud Sync

Deploy edge computing nodes near production lines for latency-free decisions, while using cloud analytics for long-term insights.

Step 4: Empower Human Operators

Introduce training programs using augmented reality (AR) and digital twins to ensure staff can interact confidently with new systems.

Step 5: Continuously Optimize

Establish a performance feedback loop using KPIs for downtime, energy use, and safety metrics.

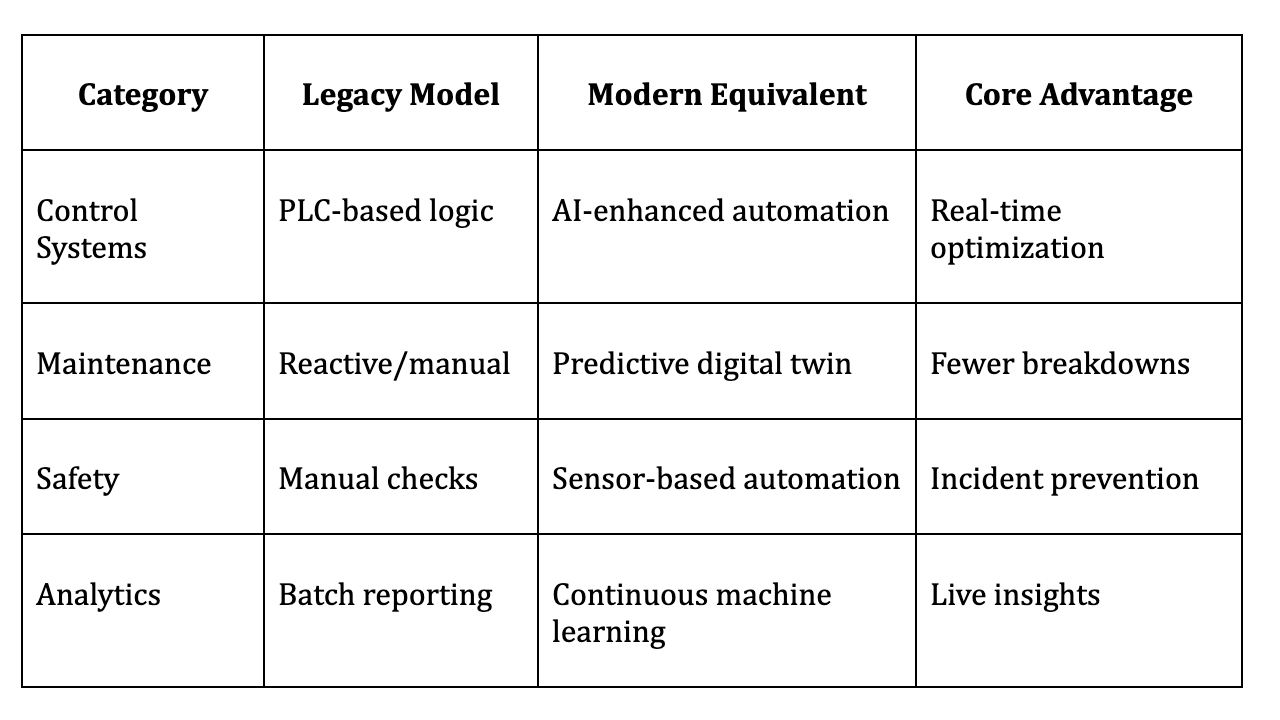

7. Comparative Technology Snapshot

8. Spotlight: Intelligent Safety Management Software

Modern industrial safety management software turns compliance into proactive protection. By unifying data from wearables, IoT sensors, and site reports, platforms like Intelex’s EHS Management Platform enable real-time monitoring, risk prediction, and automated incident response.

The result is fewer accidents, faster corrective action, and measurable gains in workforce well-being—proof that smarter software can make safety both data-driven and human-centered.

9. Glossary

Automation and Control Systems – Integrated technologies that manage industrial processes through real-time data and machine logic.

Digital Twin – A dynamic, digital replica of a physical process or asset.

Edge Computing – Localized processing that enables immediate system responses.

Predictive Maintenance – Maintenance approach that uses analytics to anticipate failures before they occur.

IoT (Internet of Things) – Network of connected sensors, machines, and systems exchanging operational data.

Machine Vision – Cameras and algorithms that detect visual anomalies or hazards.

Interoperability – The ability of various systems to communicate and share data seamlessly.

The modernization of industrial workspaces isn’t a luxury—it’s a survival imperative. Technologies such as automation control systems, IoT sensors, and predictive analytics are driving measurable results: reduced downtime, safer conditions, and improved output quality. As safety management platforms and AI orchestration tools converge, organizations that invest in integrated intelligence today are setting the benchmark for industry 4.5 and beyond.

Elevate your business leadership skills and create a thriving work environment by exploring the resources at Breakfast Leadership. Discover top-ranked podcasts, insightful articles, and strategies to enhance your brand and team success!